Work Orders

Create Work Order

After signing in successfully, click on Create Work Order tile.

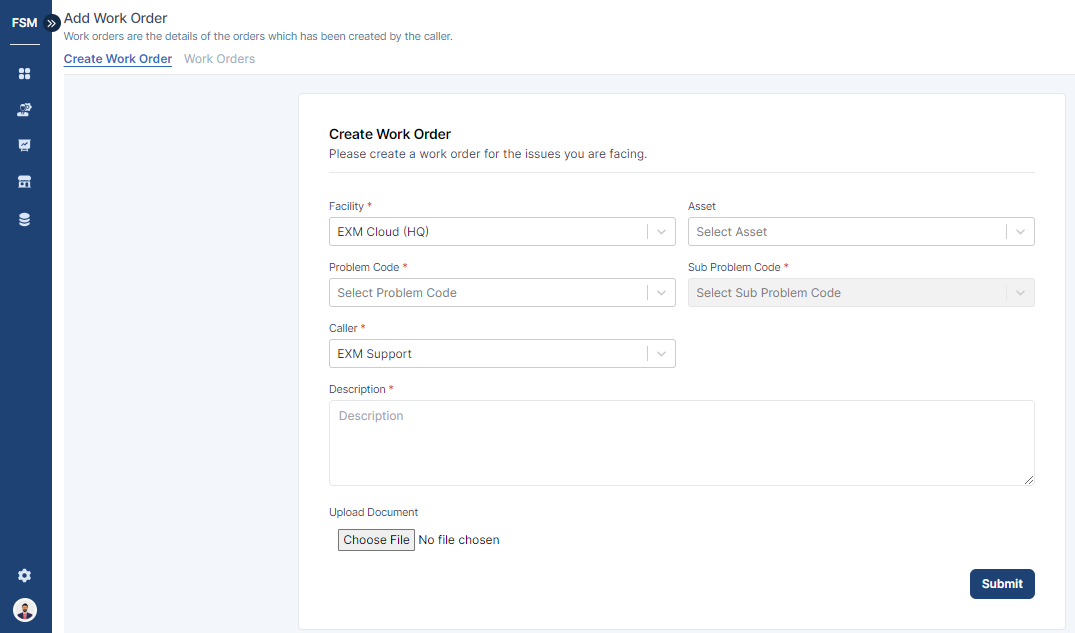

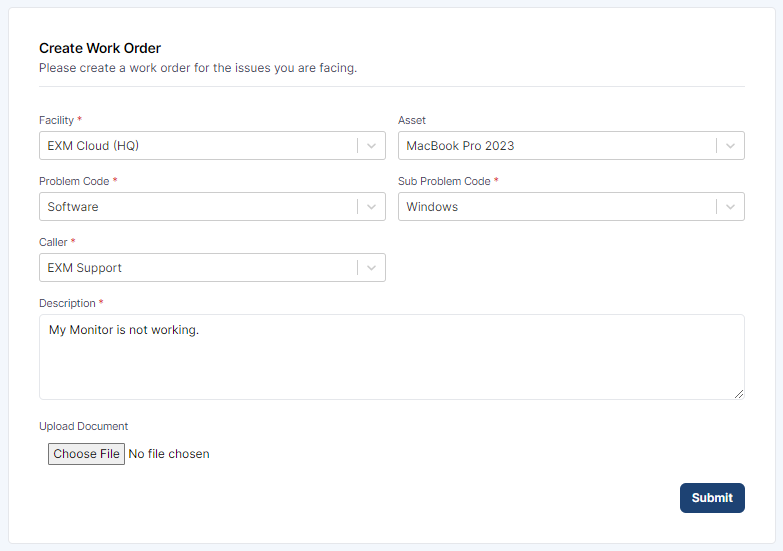

The form shown below will appear on the screen, allowing the user to create a work order.

The user must complete the following fields on the form:

| Field | Description |

|---|---|

| Asset | Parts required to execute the work order. |

| Caller | Person reporting the Work Order |

| Description | Detailed explanation of the Work Order |

| Facility | Location of the current user. |

| Problem Code | Type of issue. |

| Sub Problem Code | On Selecting Problem Code, select the Sub Problem Code, if applicable. |

| Upload Document | Add files related to the Work Order |

The Facility, Problem code, Sub Problem Code, Caller and Description fields are mandatory however the user can upload document, or image file while creating the Work Order. |

After the Create Work Order form is filled, click on the “Submit” button.

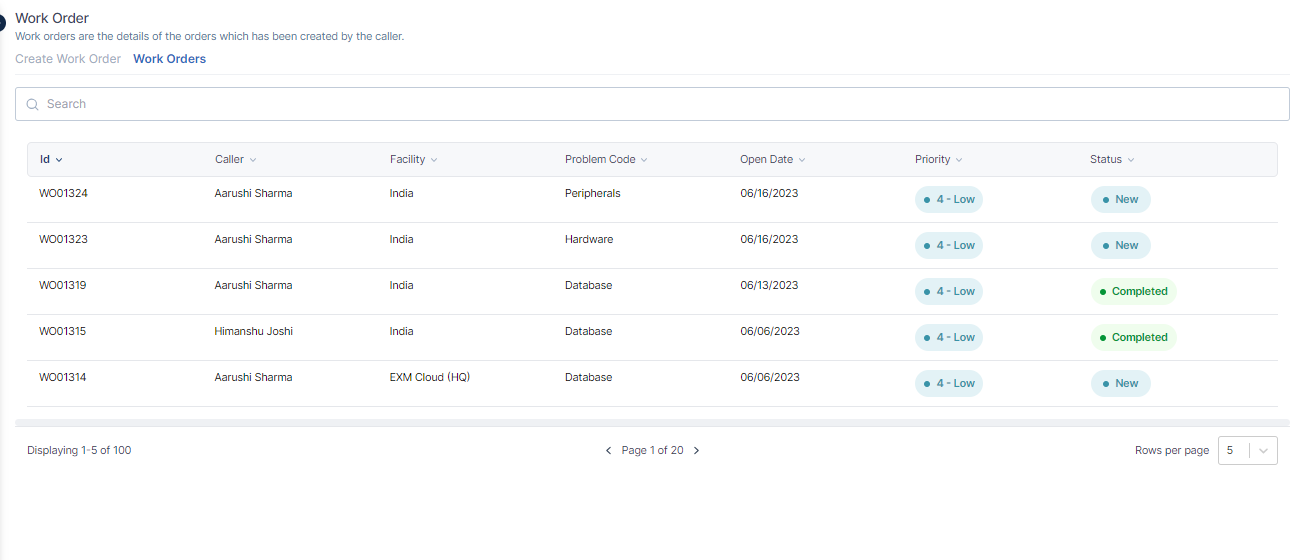

View Work Orders

On successful submission, user will be redirected to the Work Order view or click on Work Orders tile to view all the created work orders.

The list view will open and users can view the details for each work order.

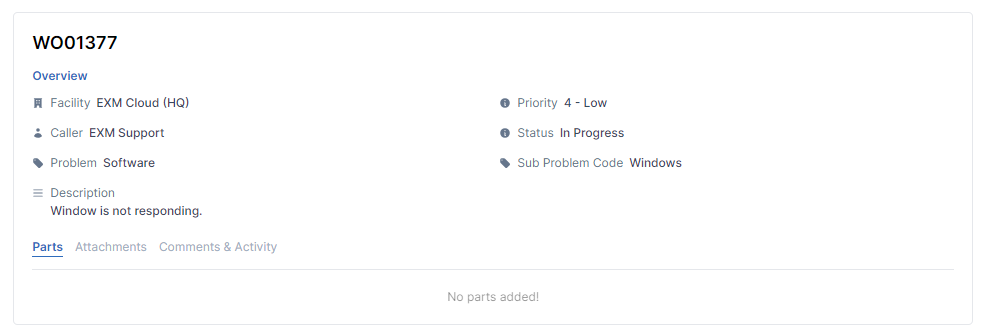

Clicking on the most recent work order will bring the user to a screen where they can view all of the work order's data.

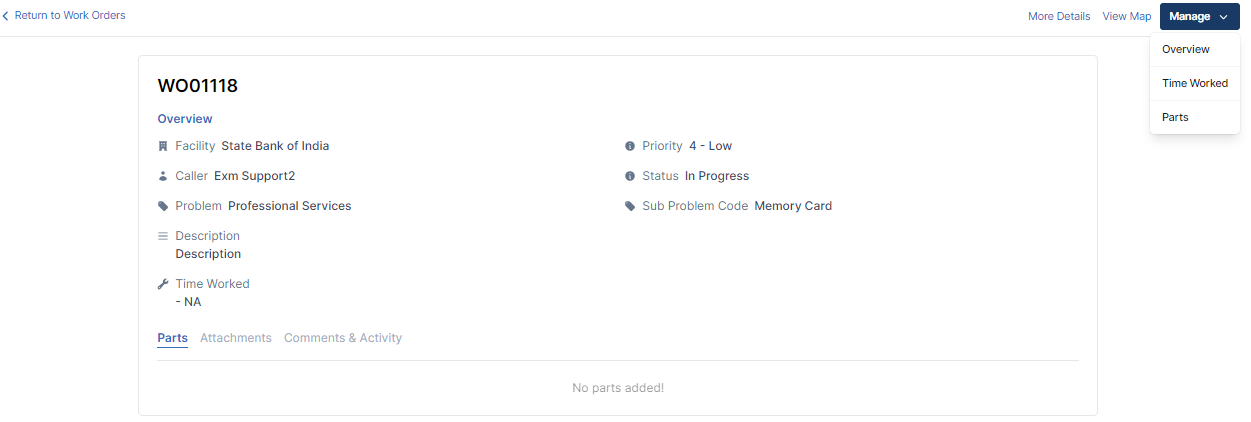

Edit Work Orders

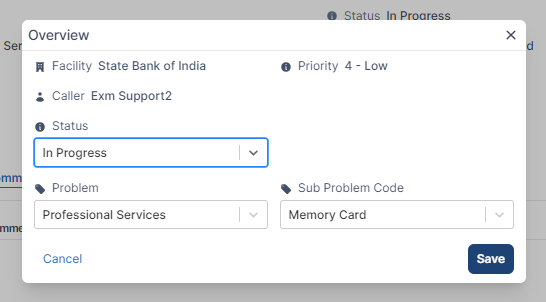

The designated agent/technician has the capability to modify work orders. To do so, they should click on the Manage button located in the top right corner, then choose Overview from the drop down menu.

Facility, Priority, Caller |

Status, Problem Code, Sub Problem Code, Time Worked |

Agent can edit the status of work orders accordingly. If the work is in process, status can be updated to In Progress. If the work is paused, status can be updated to On Hold and On Hold reason is mandatory. If the task is complete, status can be updated to Completed and Resolution Notes are mandatory.

Time Worked

Agents also have the ability to input the time they've dedicated to a specific work order for its completion. They can accomplish this by navigating to the "Manage" option located in the top right corner and selecting "Time Worked" from the dropdown menu.

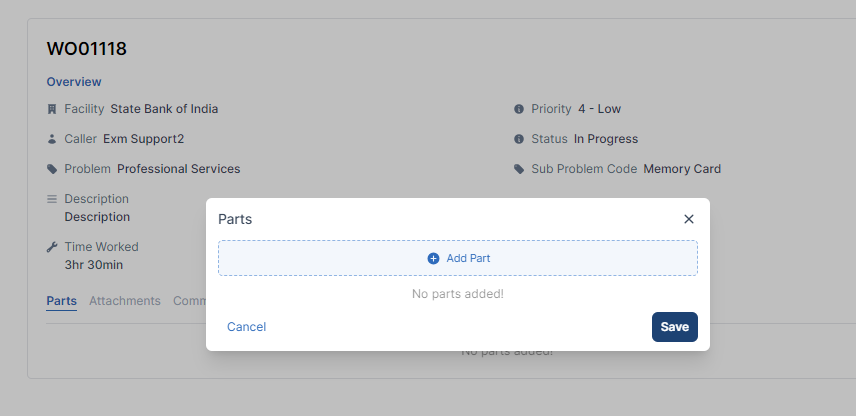

Parts

The role of parts used in a work order is to facilitate the completion of service tasks by providing the necessary components or materials required for repairs, installations, or maintenance. All the parts utilized in a work order to make it complete can be added or removed from this section.They can accomplish this by navigating to the "Manage" option located in the top right corner and selecting "Part" from the dropdown menu.

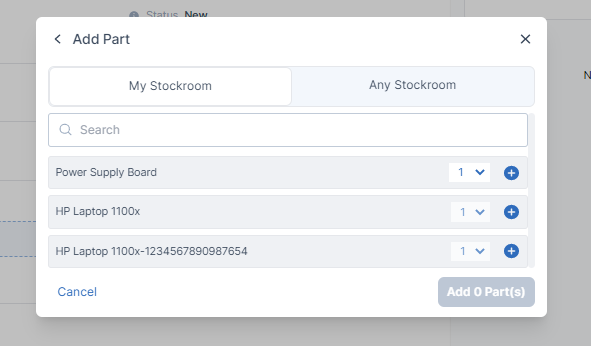

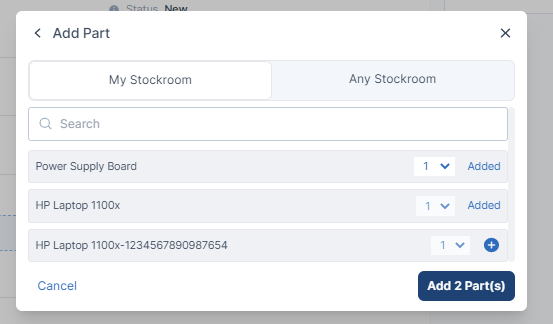

The required parts can be added by clicking on button.

Parts can either be added from My Stockroom or from Any Stockroom. My Stockroom has all the parts listed from the field agent's truck who is working on this work order. If the parts are not available in the field truck, they can be transferred and used from any other stockroom which can also be a warehouse.

To add the parts, select the quantity required to fulfill the work order and click on Add Parts.

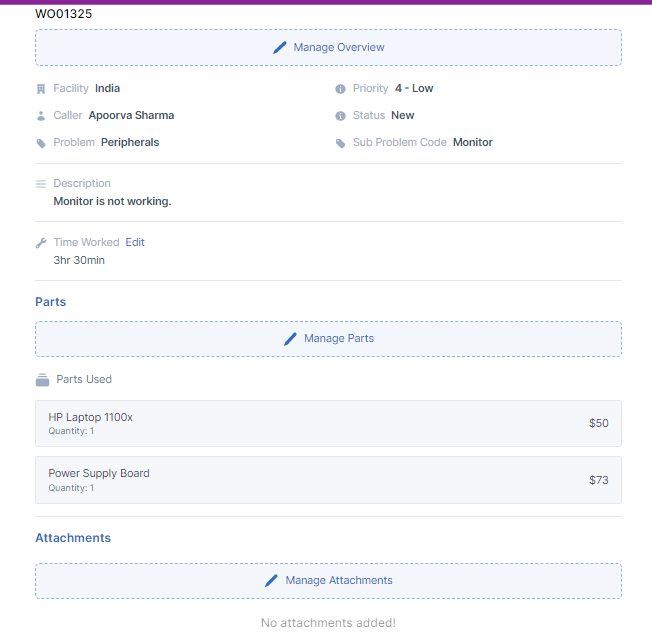

The selected parts and the cost associated with them will be shown in the Manage Parts section which can further be edited/removed.

Comments & Activity

The Comments & Activity section in a work order management system functions as a central repository where users can contribute to and review a detailed log of comments and activities associated with a specific work order. Agent have the ability to post comments and attach files or documents to provide additional context or information relevant to the work order. This section captures updates, notes, and discussions from various users involved in the work order process, ensuring a comprehensive record of communication and actions taken. Additionally, it facilitates quick access to all emails sent out by the system. Users can utilize this section to both contribute to the ongoing discussion and review the history of communication and attached documents related to the work order, thereby enhancing collaboration, documentation, and transparency throughout the work order management process.

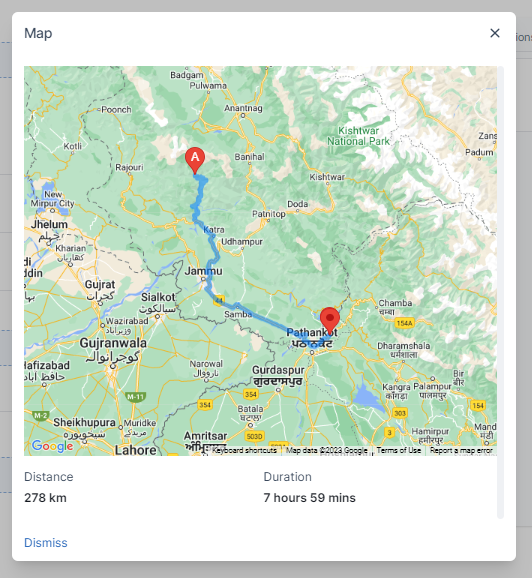

View Map

It gives the distance between the Work Order Facility and the current user location.

To view the map, click on button.

Check In/Check Out

In a work order system, "Check In/Check Out" lets technicians or field workers show when they're ready to start or finish tasks. Checking in means they're ready to work, while checking out means they're done. This helps track task time and ensures they complete their work. It makes managing work orders easier and keeps track of task progress.